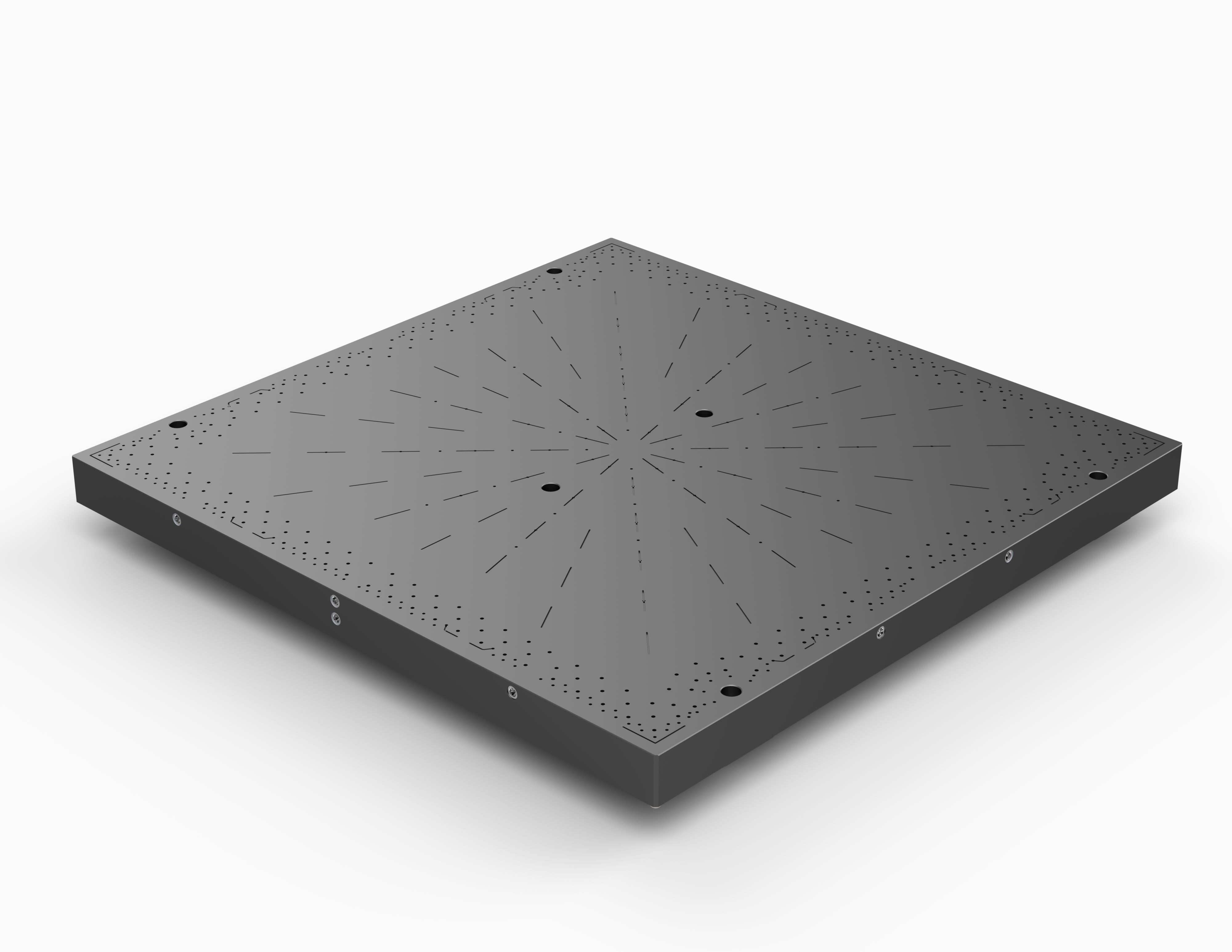

DALIAT-EL CARMEL, Israel, Sept. 19, 2024 /PRNewswire/ -- CoreFlow Ltd., a leading supplier of innovative vacuum stages for the semiconductors and FPD industries, today announced the launch of the GripJet™ vacuum stage for handling and flattening highly warped panels for the emerging Fan-out Panel Level Packaging (FOPLP) high-volume production lines.

According to Brad Perkins, product line director at Nordson Test & Inspection. "Glass substrates have their own sets of challenges. When you look at a 500-plus millimeter square for those large glass panels, you run into some challenges with how much that bends and warps, and then how do you hold them?"

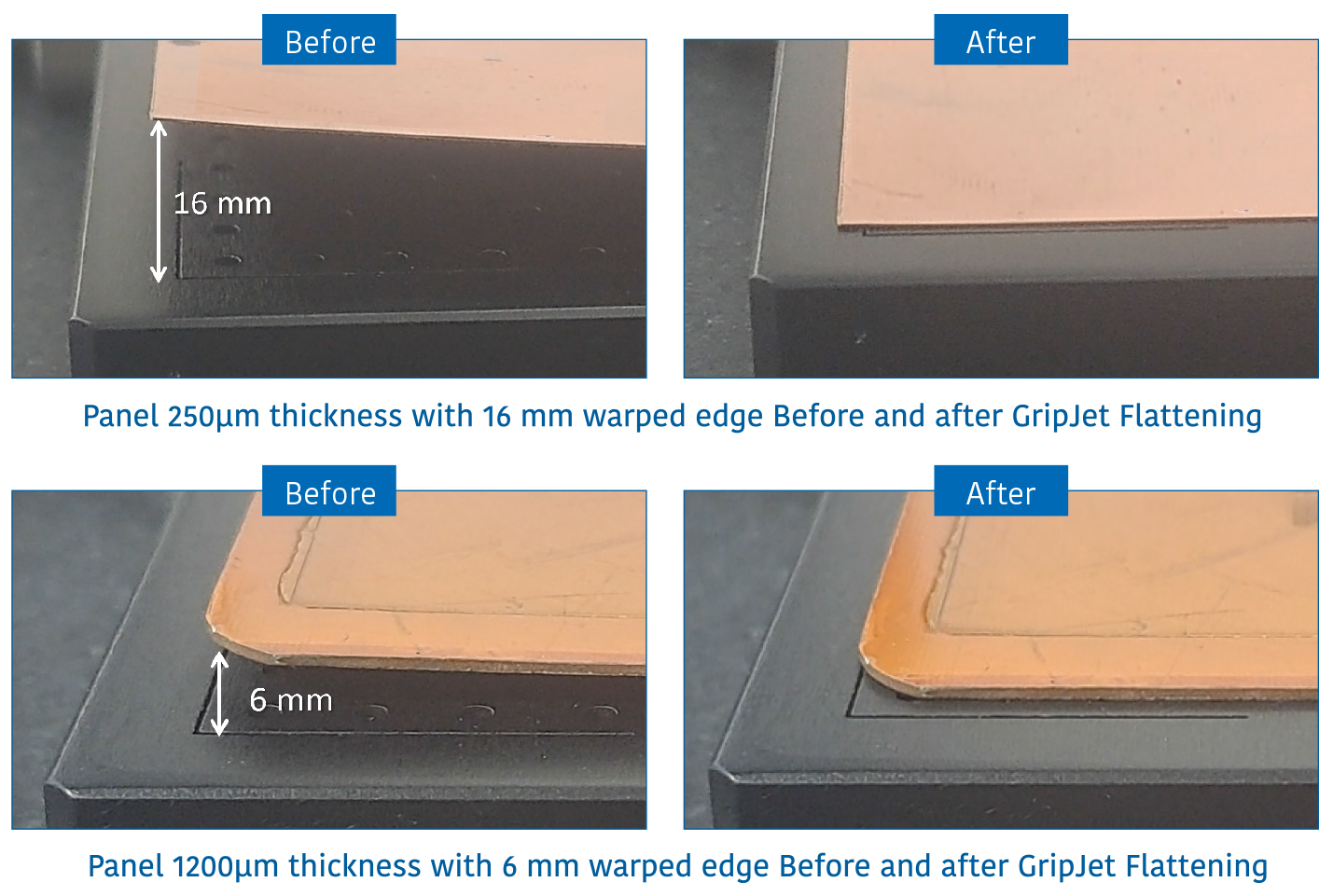

The GripJet™ vacuum stage employs the SmartNozzle™ selective vacuum technology with a patent-pending GripJet flow amplifier to generate a powerful vacuum force, effectively gripping and flattening highly warped panels into a flat stage. This innovative vacuum stage technology eliminates the reliance on traditional soft vacuum pads, mechanical clamping mechanisms, or the use of huge vacuum pumps (as often needed for standard vacuum stages) resulting in enhanced productivity, reduced breakage, reduced cost, improved yield, and increased tool uptime.

Live https://youtu.be/PeBkpkZmgqQ

The GripJet™ vacuum stage is available for standard industry panel sizes such as 510 mm X 515 mm and other customized sizes for Glass and copper-clad flat panels of various thicknesses and warpages. The GripJet™ stage was designed for seamless integration into existing production tools with 3 mechanical contact points, four 10 mm standard vacuum tubes, and one CDA input. Optional edge exclusion version and lift pins mechanism are available on request.

"We are thrilled to be among the first in the market to offer an efficient, production-ready solution for the emerging panel-level packaging market," said Alon Kapel, Vice President of Sales and Marketing at CoreFlow. "The GripJet™ vacuum stage gives tools manufacturers a time-to-market advantage by providing a straightforward, easy integration and field-proven solution for handling and flattening highly warped panels with easy integration into FOPLP metrology, inspection (AOI), and various atmospheric process tools. CoreFlow also provides build-to-print GripJet™ stages, ensuring optimal integration into the OEM environment.

PLP GripJet Video Demonstration:

- Thickness: 0.3 mm | Panel Size: 510 x 515 mm | Warpage: 25 mm: Video Link https://youtu.be/4JPwtO4I75k

- Thickness: 1.2 mm | Panel Size: 510 x 515 mm | Warpage: 10 mm: Video Link https://youtu.be/Lvtyj3ygLTA

- Thickness: 2.0 mm | Panel Size: 510 x 515 mm | Warpage: 6 mm: Video Link https://youtu.be/eONt9DccC4o

US (English)

US (English)  Japan (日本語)

Japan (日本語)  Taiwan (繁体中文)

Taiwan (繁体中文)  China (简体中文)

China (简体中文)  Korea (한국어)

Korea (한국어)