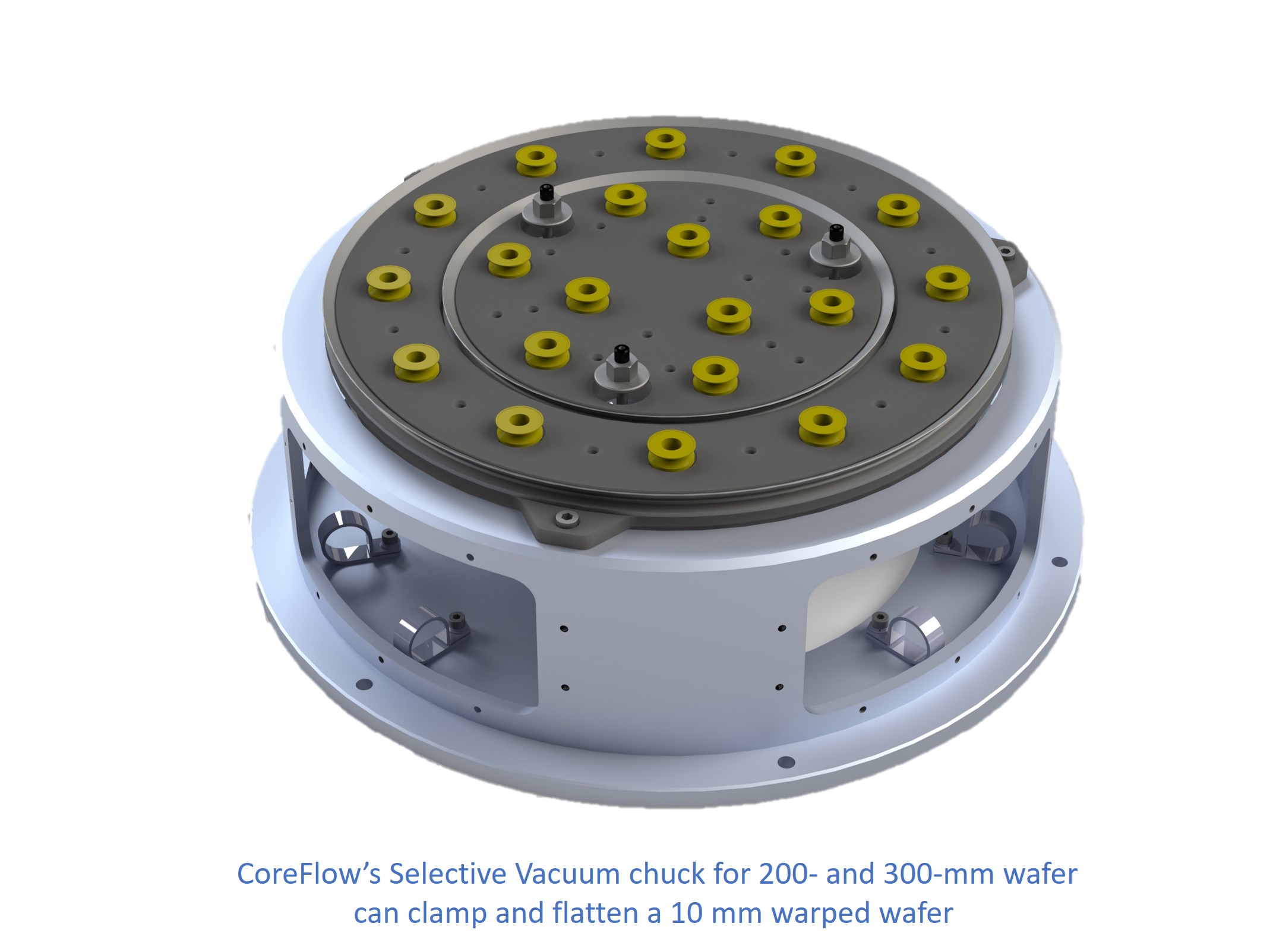

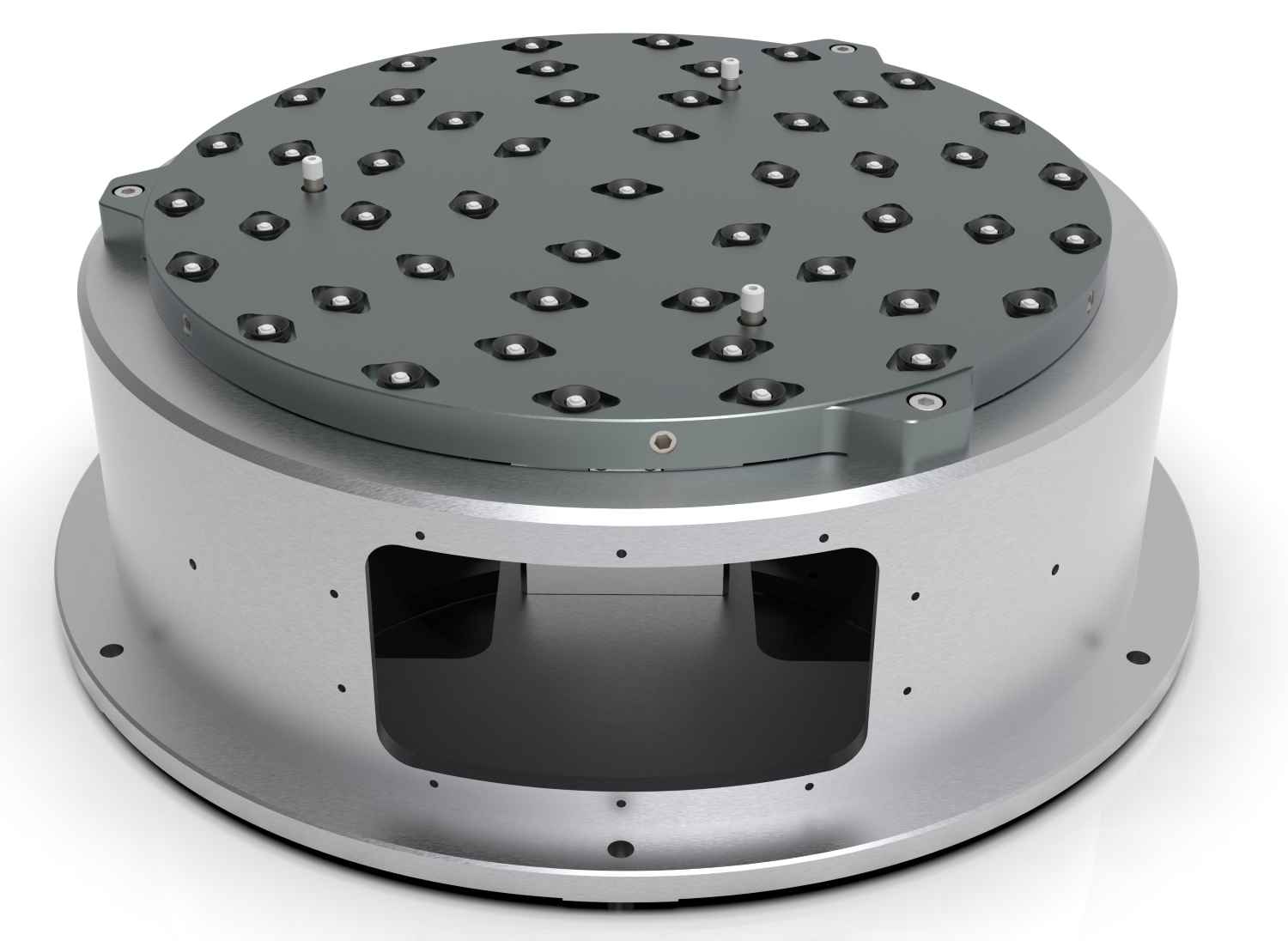

CoreFlow’s Selective Vacuum (SV) solution addresses the challenges of handling warped substrates. When a warped substrate is placed on a selective vacuum chuck or a stage, some of the vacuum ports (pads) may be uncovered and exposed to air. With a standard vacuum chuck or stage, the flow will go to the exposed ports. As result, the covered ports will not have the necessary vacuum gripping force needed to acquire the substrate.

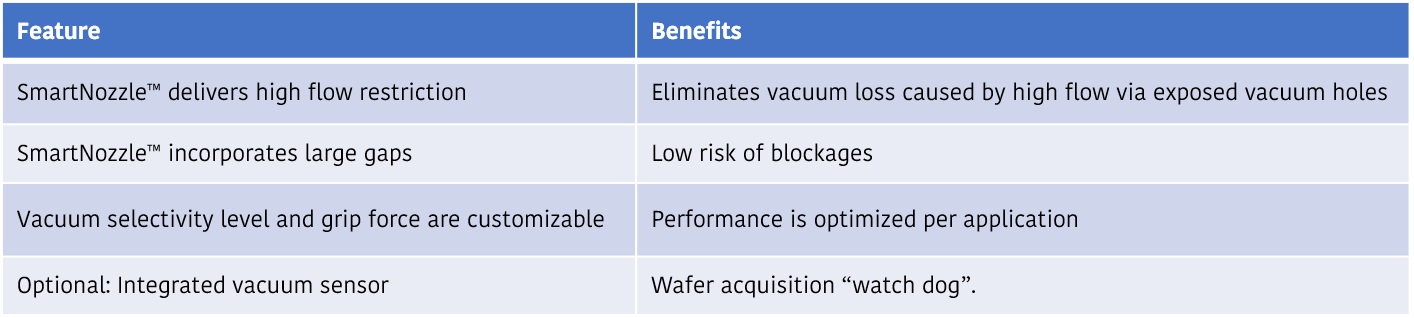

Utilizing our SmartNozzle™ technology, CoreFlow’s Selective Vacuum mechanism acquires the substrate even when only a fraction of the vacuum array is covered by the substrate. The selective vacuum mechanism ensures that all vacuum ports receive enough flow, regardless of their coverage. The flow at the uncovered vacuum ports will be choked by the nozzle’s flow resistance, while the covered vacuum ports will have access to the required vacuum force needed to grip both flat and warped substrates.

CoreFlow’s Selective Vacuum chuck acquires substrates in a variety of manufacturing applications such as Handling of warped wafers, Laser Scribing, Lithography, Metrology inspection, and more.

Product features and benefits

>>> Click on the below picture for the Video Clip <<<

.

US (English)

US (English)  Japan (日本語)

Japan (日本語)  Taiwan (繁体中文)

Taiwan (繁体中文)  China (简体中文)

China (简体中文)  Korea (한국어)

Korea (한국어)