Advance packaging techniques have transitioned from traditional round wafers to rectangular panels, with a focus on enhancing productivity and cost-efficiency while accommodating larger form factors. Panel-Level-Package (PLP) and other cutting-edge manufacturing methods significantly affect panel flatness, giving rise to warping issues that pose challenges to conventional vacuum stages and reduced manufacturing yield.

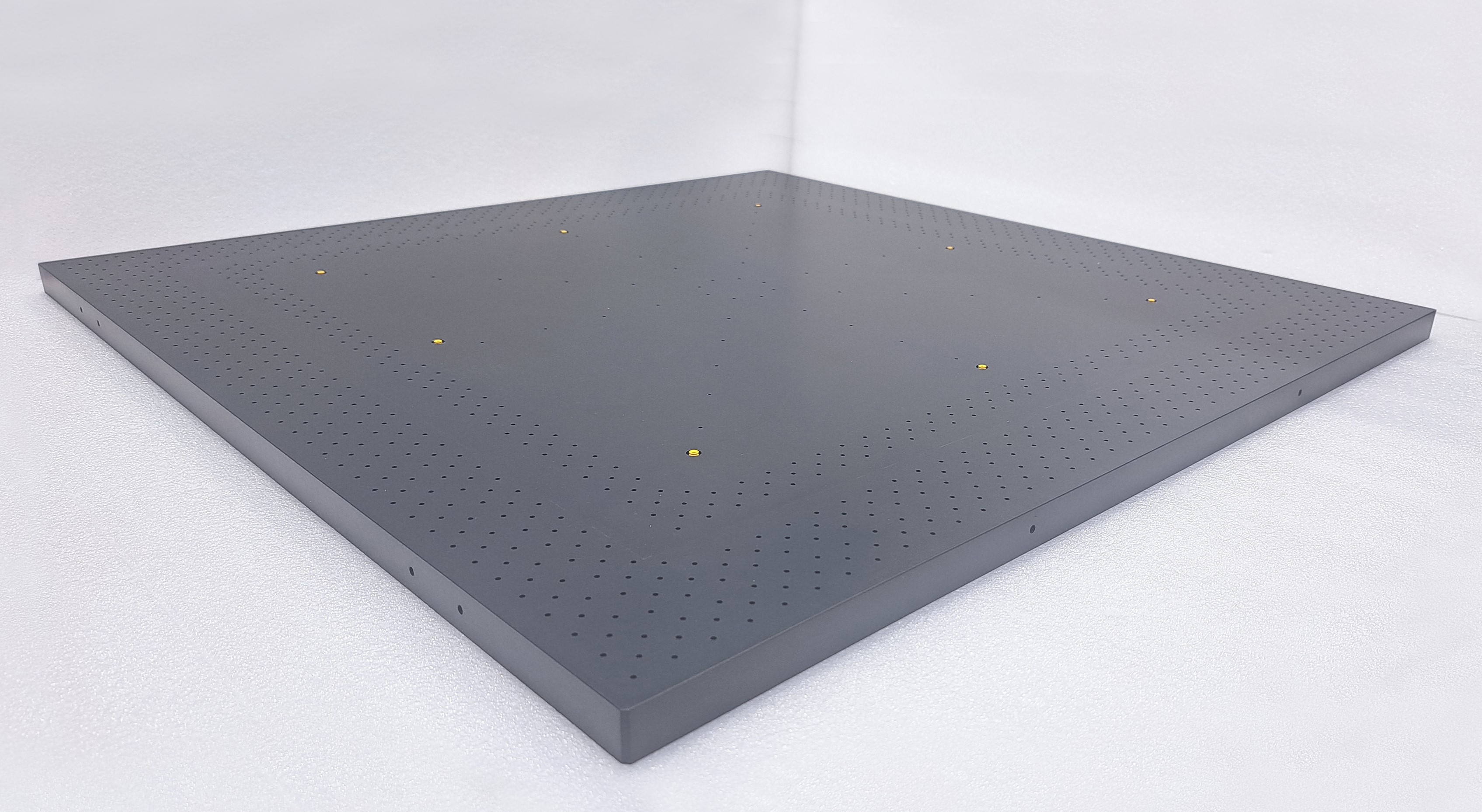

CoreFlow's GripJet™ stage technology adeptly overcomes these challenges by securely gripping and flattening warped panels and substrates, leading to improved productivity, cost-efficiency, and tool uptime. Our patented technology excels at effectively flattening highly warped panels and substrates, presenting a robust solution to vacuum handling challenges in the semiconductor industry.

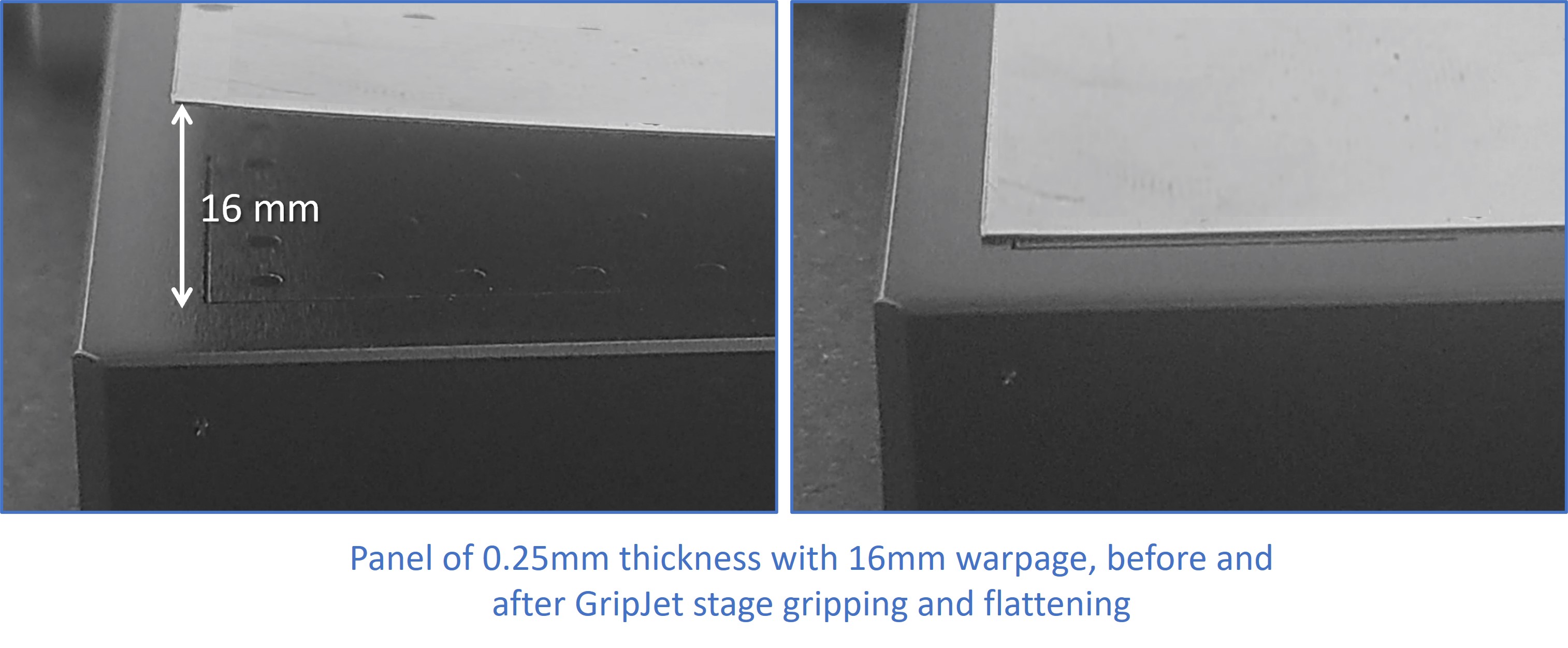

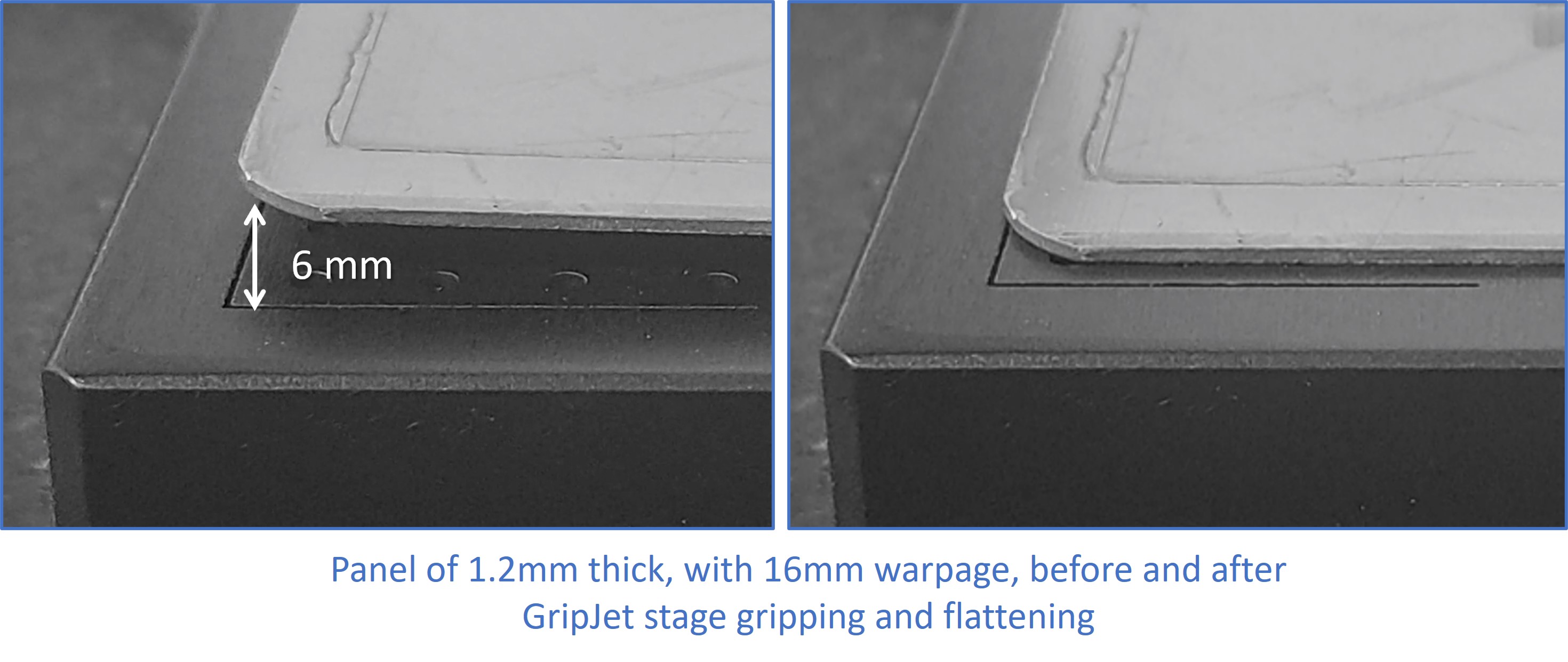

GripJet™ technology leverages a unique flow amplifier to augment the vacuum flow rate, enabling it to grip and flatten highly warped panels and substrates without direct contact, eliminating the need for soft vacuum pads or additional mechanical clamping mechanisms. Notably, it has effectively flattened panels at the size of 510 x 515 mm with a warpage of up to 16 mm.

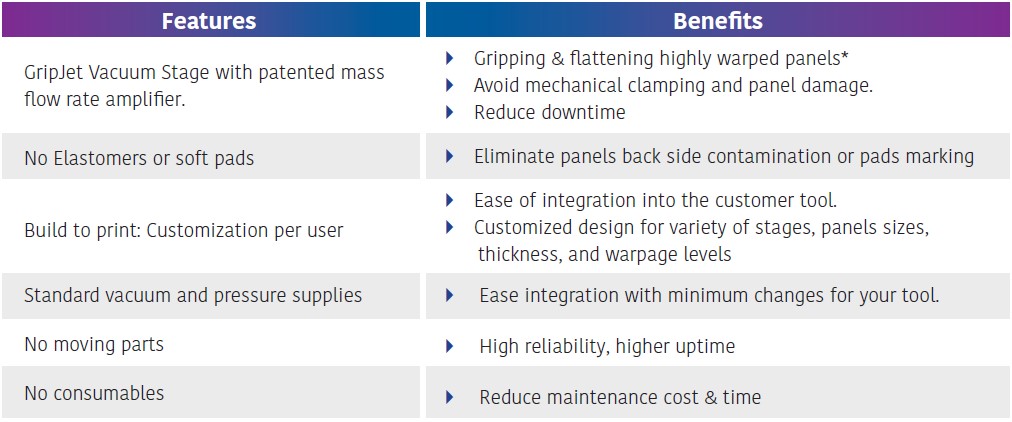

The GripJet™ stage seamlessly integrates into existing tools, compatibility with Class 100 environments, and guarantees high reliability and cleanliness. Its design is free from moving parts or elastomers contributing to its exceptional performance.

GripJet™ stage is designed for :

- Applications: Panel-Level Package (PLP), PCB, Glass carriers, and others.

- Processes: AOI, Metrology, Defect Inspection, Lithography, and other process in an atmospheric environment.

- Substrates: FR4, Glass, Copper-clad substrate, Organic substrates, and others.

Features and Benefits:

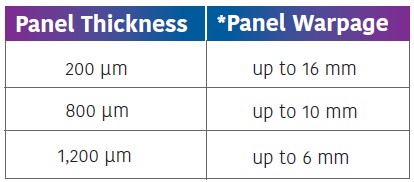

Warpage Range :

GripJet™ Stage for multi-size Panel-Level-Package substrates

US (English)

US (English)  Japan (日本語)

Japan (日本語)  Taiwan (繁体中文)

Taiwan (繁体中文)  China (简体中文)

China (简体中文)  Korea (한국어)

Korea (한국어)