With hundreds of installations worldwide, including state-of-the-art G10 stages, CoreFlow provides proven, best-in-class air floating solutions for FPD Automated Optical Inspection (AOI) applications. CoreFlow’s handling platform integrates into AOI systems to provide consistent and reliable handling of glass substrates, with maximum positioning accuracy.

The non-contact, aeromechanical stage utilizes CoreFlow’s unique Air Cushion and SmartNozzle™ technologies, which ensure substrate stiffness and flatness, while maintaining highly accurate vertical positioning of up to ±5 μm.

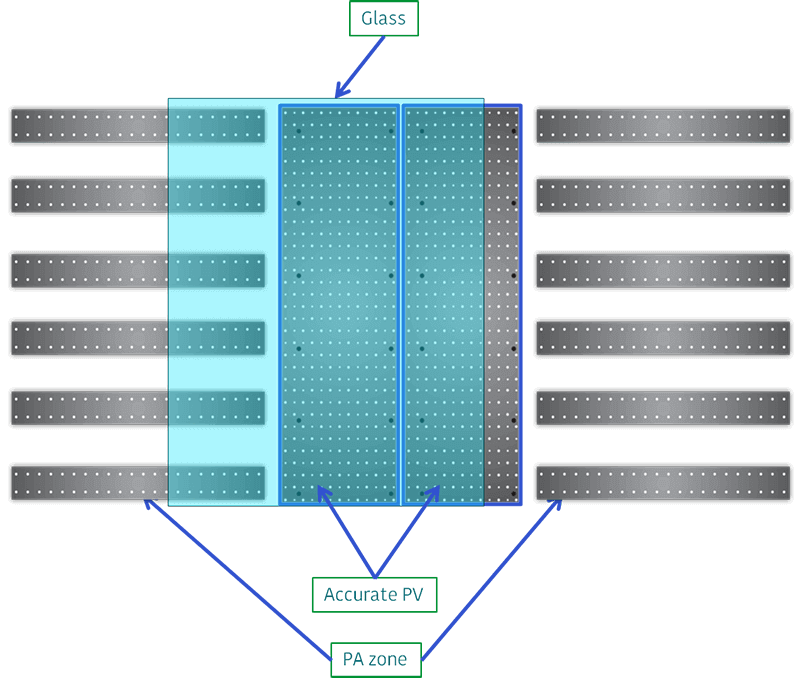

CoreFlow’s solution employs a rigid-rail, air-bar structure with a simple pneumatic design that is connected to a high-accuracy PV stage in the inspection zone.

The PV stages are located at both sides of the scan line, providing a highly accurate air gap above the inspection area and the backlight at the scan line. This stage configuration enables a quick implementation and provides superior overall flatness, while utilizing low mass flow rates, thus reducing energy costs.

Key features and Benefits

- Optimal air-gap accuracy and uniform flatness

- Reliable performance across the entire inspection system

- Customized air-bars, support glass substrates of any dimension, enabling:

- Minimal number of pressure and vacuum connections

- A low number of adjustment springs

- Simple interface to system base structure

- Low air consumption (pressure and vacuum) levels save on energy costs

- The durable surface is resistant to damage from scratches, dust, and fluids

- Very few moving parts (motion system) - reduces maintenance costs

US (English)

US (English)  Japan (日本語)

Japan (日本語)  Taiwan (繁体中文)

Taiwan (繁体中文)  China (简体中文)

China (简体中文)  Korea (한국어)

Korea (한국어)