Recent advancements in manufacturing processes have revolutionized techniques, impacting substrate flatness and subsequently causing wafer warpage. This issue poses significant challenges for conventional wafer chucks, affecting critical facets of process efficiency, tool uptime, and overall yield. To tackle this challenge head-on, CoreFlow has pioneered the GripJet™ Chuck technology, distinguished by its unique patented design elements.

This GripJet™ technology is specifically engineered to efficiently and reliably grip and flatten highly warped wafers. The GripJet™ Chuck finds application in advanced wafer-level packaging (WLP) and various semiconductor processes, ensuring enhanced performance and reliability in these critical applications.

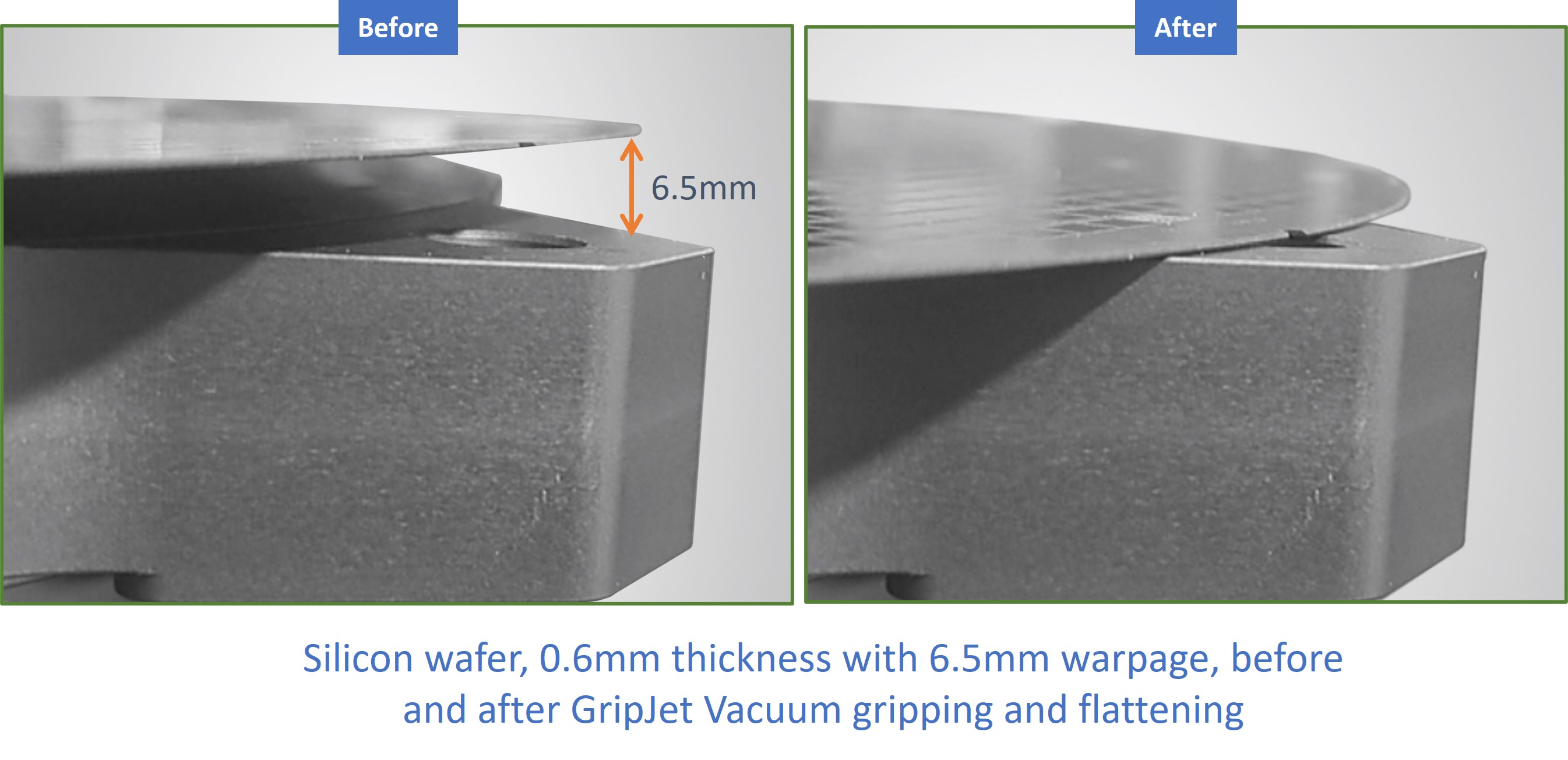

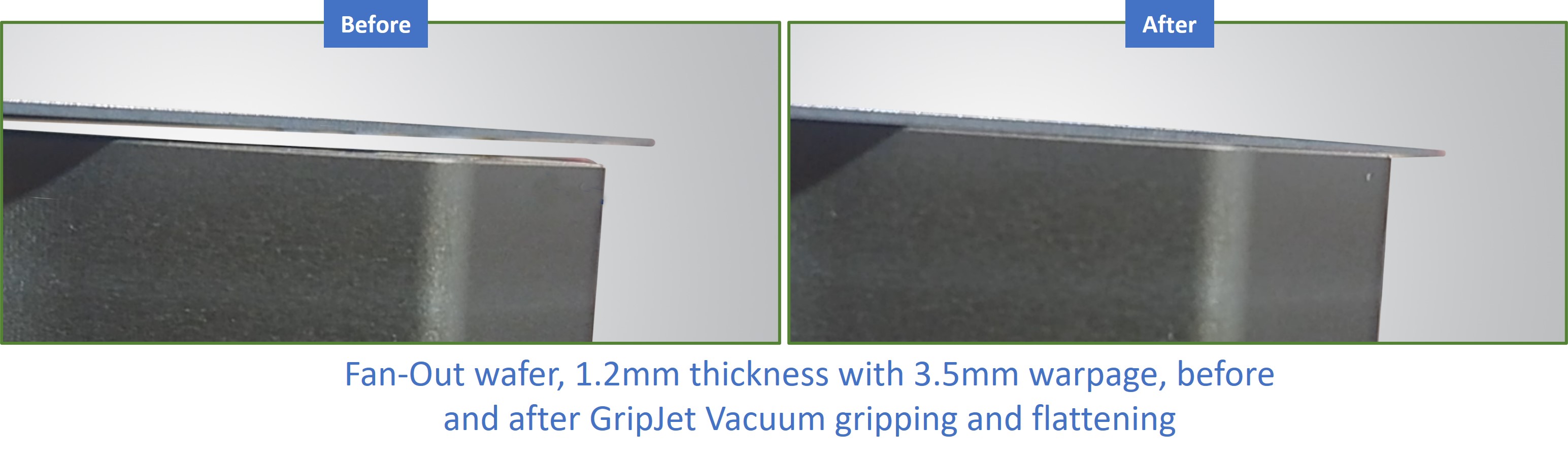

GripJet™ technology uses a special flow amplifier to increase the vacuum flow rate, allowing it to grip and flatten severely warped wafers without the use of direct contact with soft pads or any mechanical flattening mechanisms. It has successfully flattened 300mm diameter wafers with up to 8 mm of warpage. The GripJet™ chuck is easy to integrate into existing process tools, compatible with Class 100 environments, and ensures high reliability and cleanliness due to its unique design without moving parts or elastomers.

GripJet™ chuck is designed for :

- Applications: Advanced wafer-level packaging (AWLP), wafer-level chip scale packaging (WLCSP), fan-out wafer-level packaging (FOWLP)

- Processes: AOI, Metrology, Defect Inspection, Lithography, and other Atmospheric processes.

- Substrates: Silicon, Silicon Carbide, Silicon on Glass, Organic Substrates, and others.

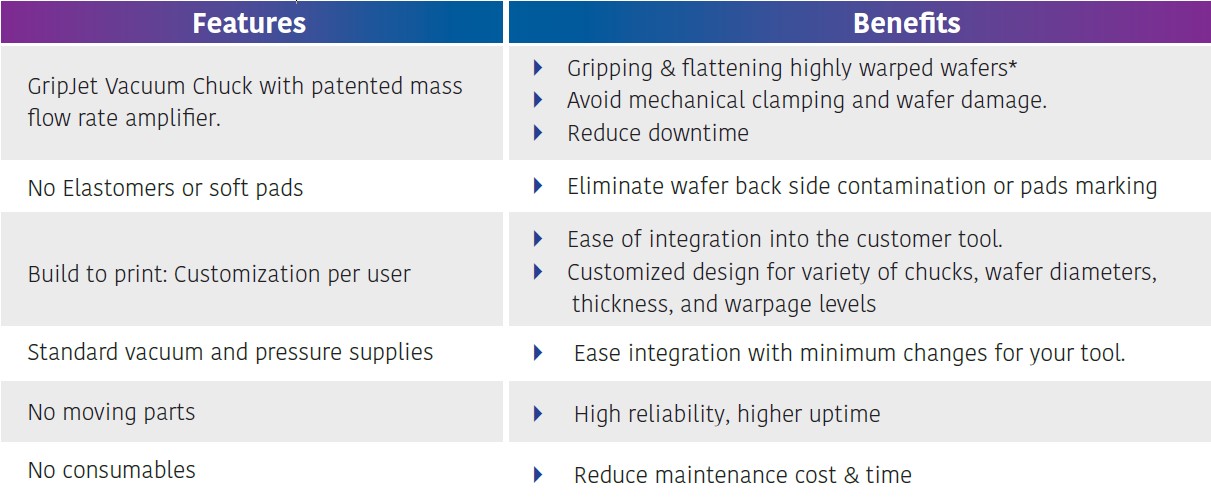

Features and Benefits:

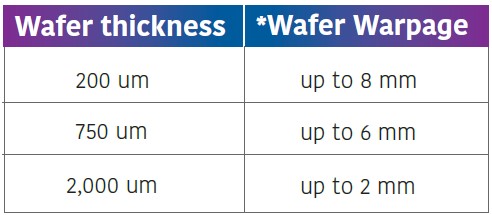

Warpage Range :

GripJet™ Vacuum Chuck for 300mm warped wafer

US (English)

US (English)  Japan (日本語)

Japan (日本語)  Taiwan (繁体中文)

Taiwan (繁体中文)  China (简体中文)

China (简体中文)  Korea (한국어)

Korea (한국어)